In preparation for the first engine restart I wanted to change the oil. This was a pretty straight forward operation. I got the front of the car up on jack stands to make accessing the oil pan easier. I then crawled under and, having pre-positioned a plastic basin to catch the oil, and used a 1″ wrench to open the plug bolt. The oil that came out was as black as pitch. I’ve read that this doesn’t necessarily indicate that your oil was worn out or too old, but it certainly doesn’t mean it’s still good. Most importantly it didn’t have little sparkles that indicate metal shavings which was my greatest concern.

Month: December 2019

Fuel system installed

The engine is now almost completely back together. The most significant section missing is the fuel rail and injector assembly which I had put together last week. All there was left to do was put it back on. I have to admit I was a bit nervous about this. The fuel will be pumped through there at around approximately 35-40 psi (depending on engine demand). That’s about the same pressure as a garden hose nozzle. If the line leaks that’s gasoline being sprayed all over a potentially hot, sparking engine. I’d prefer to not burn this car up before I even get a chance to drive it a little, so some caution is warranted here.

Continue readingDoing vacuum connections correctly

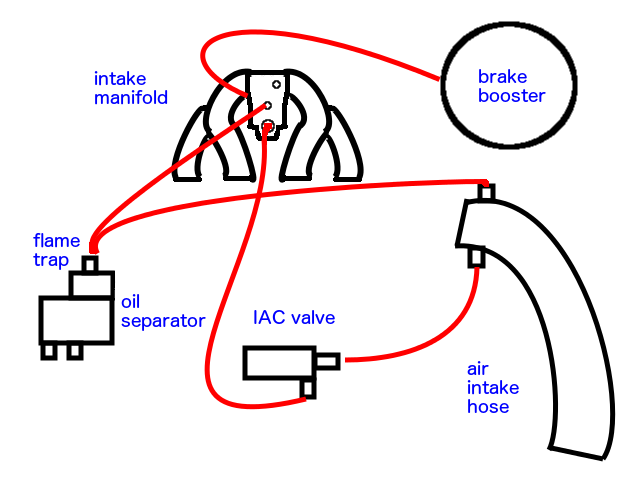

After I got the air intake system back together I spent a little time pondering a few spots in the vacuum system that didn’t seem to have any connections. My library of photos was no help, and I kicked myself for not documenting all this stuff more thoroughly. Finally I got a flashlight and peered down into the innards of the engine bay and noticed a stray hose coming from the brake booster that had no place to go. Where it seemed like it should go was currently occupied by the other side of the IAC. Then it hit me: I had the IAC going to the completely incorrect place. Where the IAC was going on the side of the throttle was where the brake booster’s vacuum line was supposed to go and the open spot on the back of the intake was where the IAC was meant to connect to! I switched them around and am now confident that everything is in the right place. To help others I drew up a simple (read: crude) diagram of where the various vacuum hoses should go.

Intake is back on

UPDATE: The vacuum hose connections featured in this entry are super wrong! Go here for the correct way to hook up the vacuum hoses.

After a delivery delay due to crappy weather and a busy weekend, I have finally been able to reassemble not just the newly cleaned oil separator but also put the intake manifold back on. The oil separator was just a matter of tightening a couple of bolt and a cable clamp. I’m sure there’s a torque setting for the two that attach it to the block, but I couldn’t find them in any of the literature I have. I tightened it to a point I like to call “not gonna fall off.”