Today’s car work started out with something a bit superficial. The windshield wiper arms had a bit of rust on them, and that would not do. I removed them all and let my younger son pitch in with the sand paper to try and smooth out the finish a little in preparation for painting. The idea was to get the surface even and ready for some shots of flat black spray paint

I took them over to my “painting bricks” in the back yard where I do all my spray painting and hit them all with Rust-Oleum flat black enamel.

The initial results look promising. The rust on one of the arms was more than just surface level and that is still a little visible, but that can be hidden by putting the ugly side downwards.

Latch Work

I then moved on to the nagging problem of driver’s side door latch not working from the inside. I have a strong belief that when leaving a car one should not have to roll down the window and reach outside to open the door. Call me old fashioned, but it’s just a conviction I hold close to my heart. I fiddled with the latch a bit, and after comparing it to the functional latch on the passenger side I saw that the mechanism just wasn’t moving up to engage enough. Mechanically it all looked sound so I guessed at there being some gumming-up going on, hit the whole thing with some of that sweet, sweet Aerokroil. A few minutes later I had a functional latch!

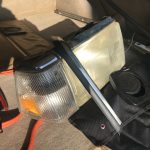

Next was the completely non-functional rear left hand door handle. I once again took the inside door panel off so I could see the mechanism and saw that when pulled the handle was supposed to pull on a spring that actuates the latch mechanism using a metal rod, but that spring had slipped off.

Easy fix, right? I got it back on pretty easily but the handle still didn’t work. Only then I noticed that one of the screws holding the handle to the door wasn’t actually there, and when I removed the other one and took the handle off I quickly saw that the handle itself was completely broken. The metal “ear” where the handle hinged had sheared off!

That’ll have to be replaced. I looked around on the web and learned that 1992 240 had a different style of handle than the model years before it. Instead of a shiny handle a matte-black one was used. But my broken handle was not matte-black. When I looked at the other three handles on my car, sure enough they were the expected black color. After seeing the prices of the genuine 1992 style handle it became apparent quite quickly. A previous owner had broken the original handle and, seeing how expensive they were to replace, decided to buy a much cheaper after market pre-92 handle with the shiny finish. They fit, but a common complaint about these after market handles was that the metal was cheap and often times broke within a few years of installation – exactly what had happened to mine. Remembering the old adage “buy cheap, buy twice” I decided the just shell out for the proper handle. When it arrives in about a week I’ll re-install it and finally have a car that all passengers can enter and exit at will.