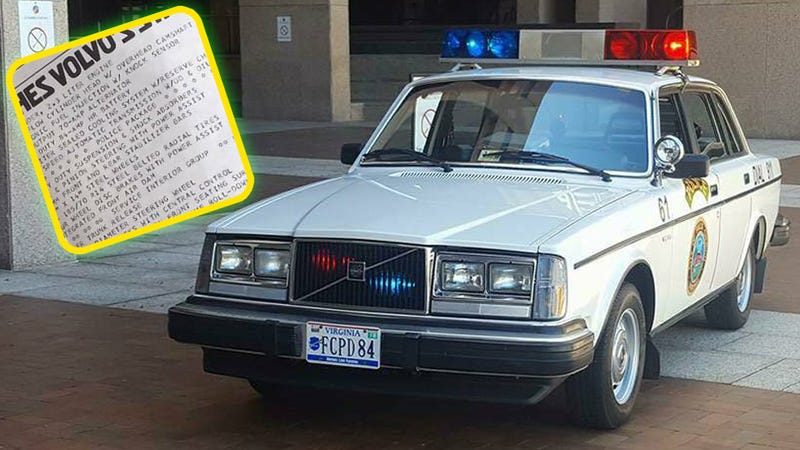

The weather this past weekend was just glorious. After a disappointingly warm and wet September we had our first real run of crisp, sunny autumn days. I made sure to carve a little time out to start the tests of the fuel system. The results turned up both good and bad things.

The Good

I began by sorting out the fuse panel which, for some reason, had a couple of fuses of the wrong amperage in the wrong places.

With those sorted I decided to test the fuel pumps for basic operation. Using a small jumper wire I had made I removed the fourth fuse from the top, which is for the primary fuel pump, and connected the right side of that terminal to the left side of the sixth fuse down. This brought power to the in-tank pre-pump which started right up with a faint hum from the rear of the car. I put the fuse I had removed back in and applied attached the wire to its left side. This powered the primary pump which also began to hum nicely. With the pumps running I tried starting the car. Success! The engine started up and this time didn’t immediately stall. After some warming up it did sustain itself at idle, albeit roughly. This tells me that the fuel pump relay is kaput. I immediately ordered a replacement, thankful to only be buying a relatively inexpensive relay rather than a much more expensive new pump. The rough idle is probably due to bad timing. A friend has a timing lamp which I’ll use to correct that.

I also got around to attaching the rear windshield spray nozzle. I’m not getting any spray out of it right now, but like the front I’ll just have to clear the line. Unlike the front one the routing of that hose is a bit less accessible so hopefully this won’t be too difficult.

The Bad

While clearing the front windshield spray nozzles my driver side hood hinge decided that it would much rather start hinging sideways rather than up and down.

With my daughter’s help I attempted to straighten and reattach it, but the damage seems to have been done. The next attempt to close the hood resulted in the same sideways movement. I’ll have to get a new hinge. Interestingly, when I looked on eBay I saw plenty of hinges for sale but most of them are for the passenger’s side. I wonder if this means the driver’s side has a tendency to break more often resulting in a glut of single passenger’s side hinges for sale.