Now that my car can be used it’s tempting to stamp “done” on this project, but that would be supremely premature. There is still a lot to do on this car both in terms of maintenance and improvement. I’ll use this entry to list those out for future reference.

Continue readingCategory: Planning

Uncooperative Weather

The last couple of weekends around here have featured some pretty uncooperative weather, so I haven’t had a chance to do anything with the muffler. Once things line up I’ll be right on it. In the meantime I’ve noticed a strange electrical issue. When I push the brakes my license plate lights turn off and the center brake light does not turn on. I’m guessing there’s a short somewhere. That’ll require some looking into.

Coming Soon

I got half of a big shipment of parts today. This is a big deal because it’s the last big bit of equipment that I need in order to get the car road worthy and inspected. Here’s a peek.

If you guesses “new exhaust system” then you are correct. This first package has only the mid-muffler/resonator and rear muffler. The various pipes, clamps, and hangers are coming in another. I’m hopeful that they arrive before the weekend and doubly hopeful I have the time to install it all.

Getting ready to get this done

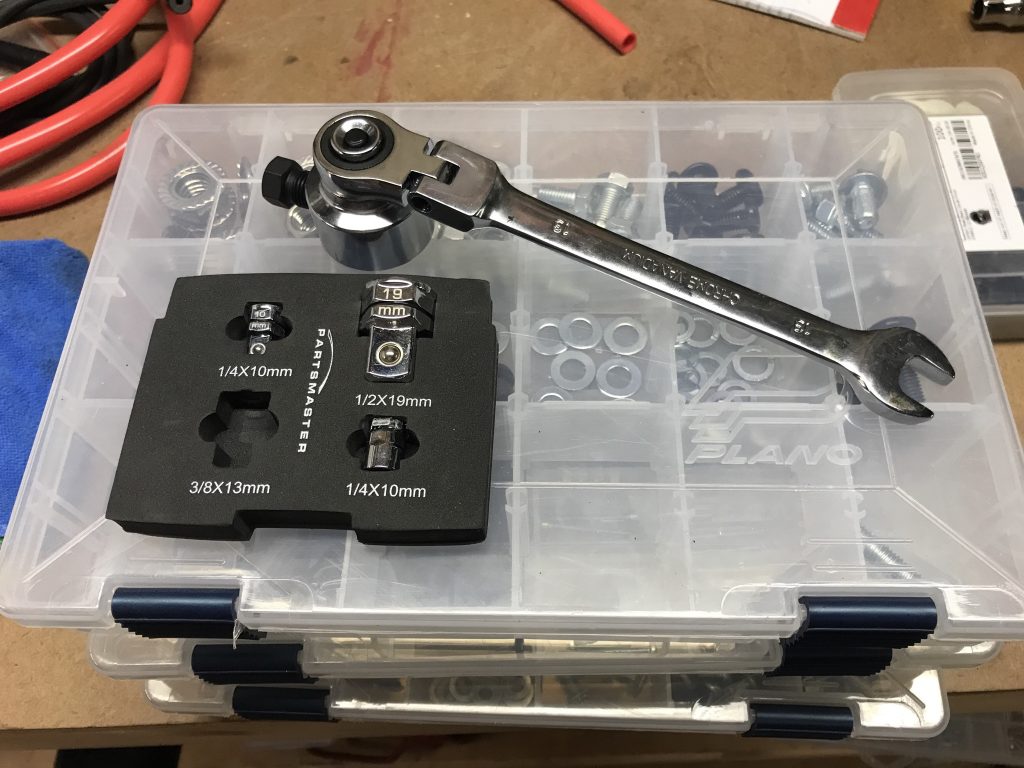

A new tool (plus a tool accessory) arrived the other day, and I think they will aid me greatly in my battle against this stupid rounded off bolt. This tool is a Go2 Socket 2.0 bolt removal tool and the accessory is a set of Zenith Industries socket adapters.

Continue readingThe good news: half way there!

After getting that set of flex head wrenches that I thought would give me the clearance and leverage on the bolts holding the overdrive solenoid, I climbed back under the car to try again. I was eager to get moving on this seemingly simple task of removing two bolts. Just two bolts? How hard could that be? Sure I learned last time that the bolts were in a location that was a bit awkward to access from below, and that the bolts themselves were very greasy and perhaps a little rounded off already. But I was ready for the challenge.

My efforts were initially promising. I got a wrench onto the rearmost bolt, positioned the handle in a way that cleared the transmission housing while still giving me some leverage, cranked on it, and… success! The bolt started moving and was soon removable with just my fingers. Five minuted in and I was already halfway done. Things were looking up! And, of course, that’s when the bottom always falls out.

Continue readingPrioritization

Now that my car is essentially drivable I feel like I should sort of my priorities moving forward, at least in the medium term. There’s plenty of cosmetic stuff I could do, but I would like to refocus more on the mechanical aspects of the car that need tending to before I return to that. The following is a list, mostly for my own reference, of the things I think I should tackle and in what order that should be done.

- Replace brake pad pins/springs and attach new front left brake guide pin. I conveniently have the parts to do this now, so it should not be difficult.

- Diagnose and fix the overdrive. I believe either the switch on the shifter is bad or that relay on the transmission is broken.

- Switch crappy controls (window switches, signal lever) with nicer ones. True that this is a cosmetic issue, and I said I was putting those off to later, but I also have these parts too on hand. I might as well get them done with.

- Finish removing window tint, clean up leftover adhesive on windows, and replace rubber window seals. The seals are allowing small amounts of water to leak into the door which is ruining the door panel. I have the rubber bits to do this already.

- Install a new exhaust system. The old mid-muffler has been shown to be deteriorating and losing effectiveness.

- Attach new wheel dust guards. As soon as I find a good source for these that aren’t terribly expensive. That’ll be a good opportunity to checkout the wheel bearings and replace the bad wheel lug mentioned in this post.

- Reattach the last few missing external trim pieces. There are two, both of which I have, plus the lower rubber door trim strips need to be re-glued.

Status Update

Just a quick update to say that I’ve been regularly starting my engine and letting it idle for a few minutes, and the effect has been dramatic. It’s much more reliable now. The stalling on start issue has been virtually eliminated. I can even start up reliably in the very cold weather we’ve had recently, and the rich idle code has yet to return. This is all very promising as well as gratifying.

The next bit of work should be replacement of brake pads, which I hope to start this weekend. Once that’s done I should be ready to take the car in for inspection. In Pennsylvania older cars like mine must pass a basic safety inspection like all cars and a more simple emissions test that consists of making sure all the original exhaust components, like the catalytic converter and muffler, are still there and that the gas cap is not allowing fuel vapors to escape the tank. I should be all good in those departments.

Summer weather

Not much work has gotten done in the last week, and there is a reason. Two, actually. The first was that the back plate to my timing belt cover decided to spontaneously self destruct after I took it off. The two front pieces are still in relatively good shape, but the back piece was hopeless. I had to order a replacement set, and that was back ordered at iPd so it took a little show up. It has, in fact, shown up, but Mother Nature decided that we had been become spoiled with mild weather in the last month. This past weekend was in the triple digits. I am not a hot weather person in any way, shape, or form. That put a stop to my plans on reinstalling the timing belt, water pump, and accessory belts, but I assure you that as soon as the weather decides to cooperate I will be back at it. In the meantime enjoy a couple of pictures featuring my melted back cover and a side-by-side of the old and new covers complete with reproduction decal!

I’m not slacking!

I’m back!

The nasty cut on my hand has sufficiently healed to allow me to fiddle with the car again. I’ll probably have a pretty gnarly scar, but my hand still works and scars can be cool so I won’t complain. It’s also now a new year and I am ready to get to it!

Tool Heaven

There have been several developments since my accident. First, I had the supreme luck to be friends with a person whose parents are downsizing before a move. One of those parents happens to have been a shade tree mechanic himself years ago and had literal mounds of wrenches, sockets and other tools in his garage and basement that needed a new home. Some of them were a little worse for the wear, but, given a little treatment with Evapo-rust coupled with a light coating of oil, they came right back to life. So I’m pretty set for now in terms of the ability to turn bolts and screws.

New Parts

Next, I am happy to say that I managed to snag a set of good condition rear tail lights from a 240-centric Facebook group I’m on, and I got them for what I’d call “a steal.” I’ve not attached them yet as I need to test and clean up all the electrical connections, but they are very nice, especially for the price, and a far sight better than the busted ones my car used to sport.

I am also now in possession of an Engine Coolant Temperature sensor (ECT) and an intake manifold gasket. This is all in preparation for removing the intake assembly, cleaning it up a bit, replacing the ECT, and remounting it all. Additionally, harkening back to that list I found in my glove-box, I have a Fuel Pressure Regulator on the way too. Perhaps I’ll also disassemble the fuel rail and clean it out, or at least remove the injectors and clean them. I’m not sure about that yet, so stay tuned. Even further still, I went and got an overdrive bypass plate from iPd. My plan is to install that and see if I can fix the actual solenoid. If I can manage that I’ll take the bypass back off and reinstall the solenoid.

(Re)Fixing Stuff

Finally, a small amount of actual work. Sort of a revisit to previous work, really. When I had originally installed it, I hadn’t noticed that my pre-pump assembly was missing the rubber o-ring that helped keep the gas fumes from coming from the tank and into the car. So I took it back out, added the o-ring, and then sealed it back up, this time using a new and not corroded to heck lock nut. After a quick test to make sure the pump was still operating I sealed the whole thing back up and reinstalled the floor of the cargo area.

In the process I also located the previously missing center lap belt! One tiny step at a time.

Gimped hand

In a cruel twist of fate (and clumsy fingers) I have recently injured my hand with an X-Acto knife in a way that makes doing fiddly things awkward. This plus cold weather have curtailed my work on the 240 in the short term. Longer term I have a number of things lined up. This includes reinstalling the last door panel, replacing the engine temperature sensor in hopes that it improves cold start, replacing the fuel filter, and changing out the rear wiring harnesses. Look for that in the very near future (read: after I get these stitches out).

Interesting glovebox finds

When I bought my car I knew it had problems. As I’m slowly working through the issues I’ve begun to wonder what the previous owner (and those before him) had known about what the various bits and pieces of the car needed attention. This is not to say I think the PO was hiding anything or being dishonest. The car was represented as needing attention, and indeed that was a big part of the reason I bought it as well as why it was priced the way it was. I’m sure happy with the car thus far. It’s been a blast figuring it out and learning how it’s put together. But then I looked more closely at what was in the glovebox.

I don’t know why it didn’t occur to me to look through the box before I started working. I knew there were some original items in there like the owner’s manual and such, but I guess I didn’t think to much further than that. Having been the owner of a glove box or two in my day I know that they can be sort of a garbage dump. I’m glad I took the time to look yesterday because amongst all the old receipts for tires service and window tinting I found a list of what I assume were pre-identified issues.

Potential Problem List

The list was hand written, presumably by a mechanic. Among these were some I was already familiar with like the broken odometer and overdrive solenoid. Others weren’t. They included:

- Throttle position switch

- Fuel pre-pump

- Fuel pressure regulator

- Front passenger side ball joint

- Blower motor

I’m a little surprised to see the TPS on the list. It’s a simple potentiometer device that limits a 5v input signal. 0 to around 1.5V indicates to the ECU that the throttle valve is closed and a value of ~5v that it is wide open. That should be pretty easy to test if not a bit expensive to replace. The fuel in-tank pre-pump sounded like it was working but that’s not always a 100% indictor of good health. Given the idle issues I’ve been seeing there is a chance it is functional but underpowered and might merit replacement sometime soon. The fuel pressure regulator is also a bit of a surprise. The limited tests I did on it suggest it’s working fine. It’s easy to replace, but as it’s a $30-$50 part I’ll hold off until I’m sure it’s no good. Ball joints are not expensive to replace but require a bit of effort and a torque wrench. The blower motor I more or less know about as I was told the AC did not work. Replacing that is complicated and was always towards the bottom of the to-do list.

Overall I’m glad I found this paper as it gives a bit more of a handle on the list of known issues I’ll have to solve. Plus it doesn’t list anything horrible or insurmountable, even by inexperienced, shadetree me.

Timing a 1992 240 with a B230F

So after a little looking around a little it would seem that on “newer” 240s that use the Bosch LH 2.4 ECU the timing of the ignition is a function of the computer rather than the position of the distributor. This means the timing light is not going to help me out. So why the rough idle? It could be a leaking intake manifold gasket as demonstrated by this video. After I install the new relay this evening I’ll try this carb cleaner “trick” to try and find any air leaks and see if that’ll help.

Working down the checklist

I got the air side of things cleaned and back together and I’m still presented with the same issue. The car will start and idle briefly before stalling. Intermittently pressing the accelerator will sustain the engine for a second or so but ultimately it will stall. Since I’ve ticked “Spark” and “Air” off the checklist all that remains is “Fuel.” I believe this will ultimately mean fixing/replacing one or both of the fuel pumps. The main pump isn’t a problem as it’s fairly accessible. The in-tank pump will be a whole other ordeal as you generally need a special tool to get the cover’s lock nut off. It’s also possible that the fuel pump relay has gone. That would be ideal as it’s cheap and easy to replace. My Bentley manual should have testing steps, so my next move is to start there.

Making a plan

I need a plan.

As an amateur I’m mostly winging it here. I’ve taken a dirty, busted looking car that sort of ran and turned it into a cleaner, less busted looking car that doesn’t really run. Not impressive. I’m starting to think that this hasn’t been working as well as I hoped. Therefore I think I need a plan of action to get my motor running again.

Every engine needs three things in order to start and run:

- Spark – Are the spark plugs sparking correctly to provide ignition for the fuel/air mixture?

- Air – Is the engine getting enough air to enable combustion?

- Fuel – Is gasoline getting to the engine in sufficient quantities to mix with the air to enable combustion?

Spark

The most basic way to test for spark is to simply remove the plug to be tested, reattach it to its boot, and hold the shell or threaded part against a grounded part of the engine. Crank the engine, and if a spark jumps the gap then all is well. If you don’t get spark it could mean one of several things.

- The plug is bad and should be replaced.

- The plug is badly gapped. Either the ground electrode is too far away and no arc can form or it’s too close and the arc is not occurring at the correct point.

- The wire from the distributor is broken somewhere and should be replaced.

- The distributor cap’s contact points are worn out or corroded.

- The distributor’s rotor is worn out.

- The ignition coil is bad.

- The timing is off. There is a specific method to setting the timing on a 240. It might be a good idea to reset the timing if only to get experience with this process.

There are other possible causes of bad spark but those are a bit beyond the scope of what I’m working on.

Air

Air is fed into the engine through the large air intake hose that starts at the front of the car near the grille and passes through a filter, the Mass AirFlow (MAF) sensor, the throttle body, and into the intake manifold. Balancing the air and fuel mixture can be a pretty delicate thing. A leak or other unexpected mechanical failure along this path can result in too much air coming into the engine. A dirty filter might bring in too little. Some typical points of potential failure in the air intake system are:

- A malfunctioning or obstructed air box. Volvo 240 air boxes have a thermostat that allows air warmed from the exhaust manifold into the system on cold mornings and that has a tendency to seize up over time. I’ve already fixed mine (see here) so this isn’t my issue.

- A dirty and overly clogged air filter will decrease airflow. I changed the filter recently, so cross that off my list.

- A malfunctioning MAF sensor can’t accurately gauge the amount of air flowing into the engine at any given time. This prevents the ECU from properly calculating the fuel mixture and will cause the engine to run poorly or not at all. I cleaned mine recently and tested it, so, again, that’s not my own issue.

- Leaks in ducts and hoses, especially downstream from the MAF, will throw off mixture calculations. The bellow-like section after the MAF becomes brittle over the years. When I took it out originally it may have cracked, so I’ll have to inspect it carefully.

- A bad Idle Air Control valve will keep the engine from idling properly. Since my stalls are happening at idle this could very well be a problem in my car.

- A dirty throttle body will stick or otherwise not properly open and close and not supply the desired amount of air to the engine. I plan on taking mine off and cleaning it with carb cleaner.

- A malfunctioning Fuel Pressure regulator, although more directly concerning fuel rather than air, runs on vacuum and therefore needs to be inspected for air leaks and such. Its function is to maintain adequate pressure in the fuel rail. A cursory check of mine found no gas on the “dry” side so this is probably not a problem.

Some cleaning and testing are definitely in order. I’ve heard that spraying the air intakes with starter fluid and listening to see if the RPMs jump up for a moment, the idea that this fluid is being sucked into the airway and providing a brief boost to the engine, is one way to see if there are leaks. Another is to use a smoke source or fogger to attempt to spot unexpected air currents around the air hoses.

Fuel

On my car, fuel is delivered from the tank to the engine via a pump, sent at pressure through a hose, and into the fuel rail where it is injected into the cylinder for combustion. The amount of fuel sprayed and its timing is controlled by the Engine Control Unit, a computer that takes in all the data from various sensors and figures out the correct fuel/air mixture. My particular ECU is a Jetronic LH 2.4 made by Bosch (part # 0 280 000-561) in Spain. Thankfully mine is a “white label” version. Some -561 ECUs came with a pink colored label and are said to be “problematic”, so it’s nice to not have to deal with that at least.

- A faulty Fuel Pump will obviously not be able to send gasoline to the engine. The pump is inside the gas tank and requires a special tool to remove (or at least make it easier), so I don’t think I’ll be taking mine out right now. However it is possible to test if the pump is actually capable of running by jumping the 4th fuse from the top of the fuse panel to the 6th. This will bypass the fuel relay and turn the pump on.

- The Fuel Pump relay is the switch that normally controls the operation of the fuel pump. If the pump works when jumpered as described above but not when the relay is plugged in the relay is bad and needs replacement.

- There are actually two Fuel filters in a 240: one (on my car, at least) is located underneath and near the driver side wheel and the other attached to the fuel pump itself. Since I don’t know when the last time either had been changed I should do both.

- In order for fuel to make it to the engine in the correct amounts required, Fuel pressure must be maintained at the rate. For my LH 2.4 this is 43.5 psi (3.0 bar). I’ll have to test this to make sure that even if the pump is working it is working hard enough.

- Dirty injectors will mess up the fuel air mixture and either degrade or prevent proper combustion. The primitive, pre-OBD diagnostic computer on my car has already said the injectors are not malfunctioning, but I’m told that if I remove them and take them to a shop I can get them flushed properly which will help in engine performance. Food for future thought.

- If the Engine Control Unit is broken then every other part of the system becomes irrelevant. As far as I can tell my ECU seems to be working fine, and I really don’t know how to test it. As mentioned, the -561 ECUs, especially the “pink label” models were touchy, so eventually I might want to look into changing mine out for a compatible and supposedly more reliable -951 model.

It’s a pretty long list, but I’ve already ticked a couple of boxes so far, and crossing them all off the list will put me in a decent place to truly understand how all this stuff works together.