The new exhaust gasket came sooner than I thought but I didn’t have time (or good weather) to address it until this past weekend. The car stayed up on jacks for a few days. This may become significant later because after I did put the gasket in and let the car down I attempted to start the engine and got nothing but the starter cranking. This made no sense to me since the engine had run just fine a few days earlier. Did being tilted to the side on jacks for a few days somehow upset something? I can’t imagine why that would be, but what else could it be? The engine was running fine just a few days ago and I hadn’t changed anything related to it. Time for diagnostics.

Continue readingCategory: Testing

New/Old Fuel Pump and Pressure Testing

Like a lot of stories with my car and its problems, this one starts with an attempt to take a ride with my kids. One evening we all piled in for a short jaunt around town only to get nothing but cranking when I turned the key. Listening when the key was turned, I wasn’t hearing the in tank fuel pump priming as it normally does. That thing had been getting louder and louder over the last few weeks, so its sudden death was not a huge surprise.

Engine coolant temperature sensor issues

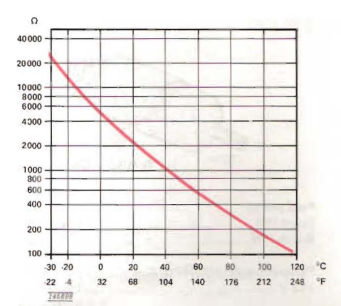

Today I attempted to test my ECT sensor. The procedure went like this:

- Boil some water

- Connect my multimeter up to the sensor

- Dip the sensor into the water and take occasional temperature readings. Compare the resistance readings to the temperature to see if they should be where they are expected

I did all this and got wildly unexpected results. Way higher resistance than I expected. For reference, here is the chart showing what I should have seen.

Looking at the sensor I noticed that it actually wasn’t Bosch branded. It was made by Spanish manufacturer Francisco Albero S.A.U (aka FAE). I’m not sure that company was ever an OEM supplier to Volvo, so I’m sort of suspecting that this sensor had been replaced at some point and that the not so good FAE replacement has since failed. Regardless, I have a Bosch replacement on the way. Since this thing is such a pain to access I want a good part going in before I reattach the intake manifold.

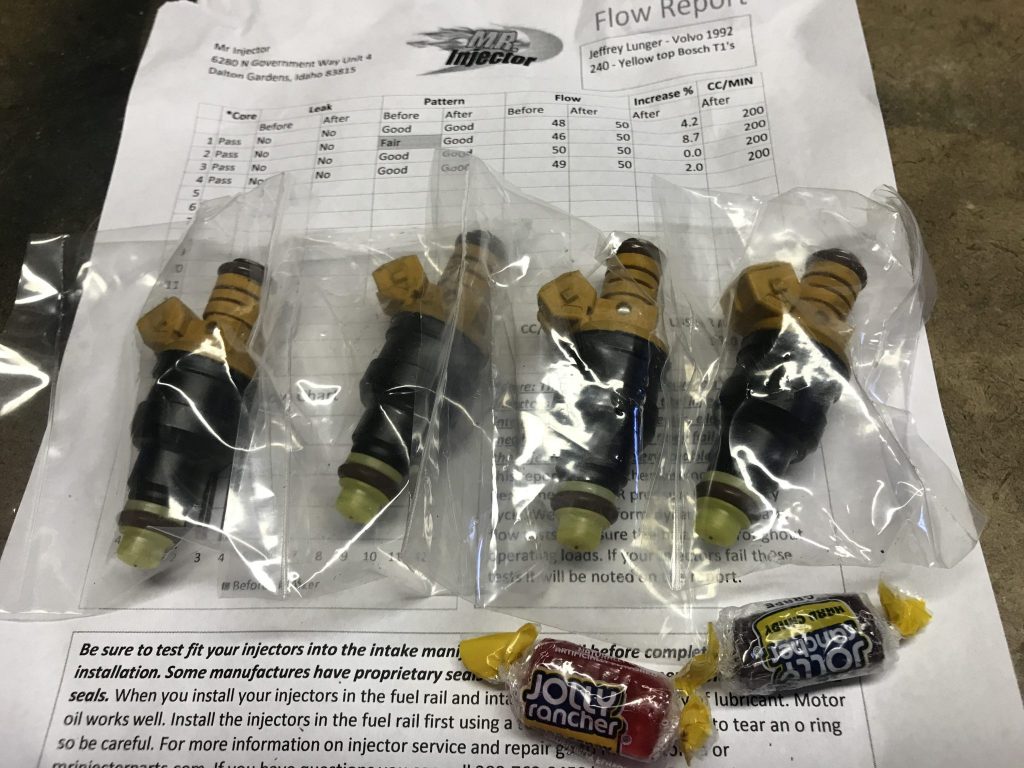

Injectors are back

After disassembling the intake manifold I was left with four loose and very dirty looking fuel injectors. I had originally intended to clean them myself, but in a moment of startling honesty I admitted that I’d more than likely either ruin them or not really clean them very much. So I looked around the internet and decided to turn this job over to the aptly named Mr. Injector. Unlike me, he has both the experience and the equipment to do this right, and his prices aren’t terrible especially when compared to having to buy new injectors because I broke one in my own half-assed attempt at fixing it. So I boxed them up and sent them off to Idaho.

His site told me that I’d be getting a baseline electrical, spray pattern, leak, and flow test followed by disassembly of the “soft” parts, an ultrasonic bath, a flush for contaminates, and finally a new set of tests to measure the improvement in function. Then they’d be oiled, have their soft bits replaced, and finally repainted with corrosion resistant paint. About a week from when I sent them they arrived back at my house and I must say I am very impressed.

As you can see they’re obviously much cleaner looking, and the flow test suggests they’re much cleaner on the inside as well. Interestingly, one of the injectors was still in very good condition while another was merely in fair shape. Overall they were still functioning quite well, but I’m glad to know that they’re now in tip top shape with new filters and pintle caps. And he also sent me candy! That’s service.

MAF: Good

This past weekend was a bit of a bust in terms of car work. Aside from several obligations, a big tree branch broke off and fell onto the roof of my garage. I did have a moment the other day to put the multimeter onto my MAF sensor to what I could see. According to my intake system green book, the MAF should show a resistance reading of between 2.5 and 4 Ohms between pins two and three, and mine was reading somewhere around 3 Ohms. A visual inspection shows the wires still intact, and I’m assuming it’s clean because I had already cleaned it many months ago and haven’t really driven since then. So, I’m willing to move this part into the “working” pile along with the IAC. Stay tuned to see if the two engine temperature sensors can go there too.

Testing the IAC Valve

The Idle Air Control valve, commonly just called the IAC, is a servo motor controlled valve that helps maintain the engine at idle according to the demands of the engine control unit (ECU). Given that my engine was having a hard time idling for more than a few seconds a failure here would not be surprising. I had already taken it off, so I figured I’d get it on my workbench and poke it a little to make sure it’s still working as expected.

Testing Procedure

The IAC is a pretty simple device. It’s a tube with a servo motor inside that opens and closes a valve to control airflow into the intake manifold. How far open the valve is depends on the voltage supplied. 12 VDC should open the valve up all the way. I also referenced the Volvo “green book” on the intake system and found that the resistance across the two input terminals should be 8 Ohms. So those are the two tests I performed. I’m happy to report that my IAC is just fine. It wasn’t difficult to test, but just in case here’s a video to illustrate how I did it.

It’s Sort of Cold Today

Like a lot of the country right now, we got hit with that “Polar Vortex” nonsense and temperatures have plunged well under freezing. I saw a number of other 240 owners trying a cold start in such low temperatures, so I figured I’d try it too. Then this happened.

I learned a lesson: when old metal gets really cold it becomes very, very brittle.

Also the car did not start, but I sort of expected that.

Oh yes, the TPS…

I forgot to mention this, but after I found the list of supposedly defective parts in the glove box I took the throttle position sensor (TPS) off and tested it out. Having done this, I must admit that my previous description of the switch was inaccurate. The 240 is much more primitive in its engine control than more modern cars. It does not measure the exact position of the throttle. Instead it merely tells the ECU when the throttle is closed and when it is wide open. The connector has three wires. One is the ground, one is for “throttle closed”, and the remaining one is for “throttle open.” Testing it means making sure there is continuity on one or the other pin (depending on if the throttle is open or closed) and the ground, and mine was fine. So I feel OK with crossing that off the “glovebox list.”

She lives! Sort of!

Last night I got my new fuel pump relay. Installation is easy. Unplug old. Plug in new. Done. Except my engine didn’t run any better. I couldn’t even get it to idle. Since it was evening and I had kids to feed I left it for the night and went back inside dejected and sad. This morning I decided to try again. My first attempts had the same results. The engine started, sputtered, and shook itself into a stall. I decided to get the engine up to operating temperature to see if that’ll make a difference, so I fed the engine gas when it came close to stall until the temperature went up. Lo and behold when warmed up the engine didn’t stall! She lives! It idled very roughly for a bit but eventually sort of smoothed out. It’s not ideal nor optimal but for now I’m calling that a success. I think for now I’ll move on to fixing the rear wiring harnesses to get everything back there working as it should. After that I will revisit the engine to try and figure out why it’s running so poorly.

After I got the car to idle I took a short video. I also noticed that my kickdown cable has come loose from the throttle, so I’ll obviously have to reconnect that. A new set of hood hinges are on their way so I won’t need to use an old rifle stock to prop the hood open forever.

Click continue to see the videos.

Timing a 1992 240 with a B230F

So after a little looking around a little it would seem that on “newer” 240s that use the Bosch LH 2.4 ECU the timing of the ignition is a function of the computer rather than the position of the distributor. This means the timing light is not going to help me out. So why the rough idle? It could be a leaking intake manifold gasket as demonstrated by this video. After I install the new relay this evening I’ll try this carb cleaner “trick” to try and find any air leaks and see if that’ll help.

Check for spark

I wanted to check for spark, but rather than do the more laborious plug-against-the-block check of the spark plugs I borrowed an in-line tester from a friend of mine. This handy tool lets you attach to one end into the installed spark plug and the other to the distributor. A light in the middle lights up when the circuit is completed. Here is a short video showing it in operation. Shout out to my son for starting the car for me while I held the camera.

It’s not easy to see on video, but the light is flashing. So I have spark on all four plugs. I also replaced the distributor cap and rotor. The old ones looked a tad corroded, and since those two parts are inexpensive I figured they might as well be changed along with the plugs.

The motor is still stalling out, so down the checklist I go.

Thread Status: Chased

The weather improved a little and I eventually worked up the nerve to chase those plug threads, and while I can’t say that it was a resounding success I can say that I was able to get the plug screwed in satisfactorily.

When I tried the ignition the car did start momentarily before it stalled out. So basically I’m back to where I started a few weeks ago. There are quite a few things that could be wrong here. I’ve covered spark, so I decided to move on to air. That meant making sure the MAF was still working, so I hooked up my multimeter.

I verified voltage on both the power and signal lines, and they were good. Next I tested resistance across the sensor saw numbers that were within the limits as shown in my manual for an LH-2.4*. There may be some air leaks messing up the calculations, but I haven’t noticed any yet.

This leaves fuel. I think my next step will be to take the throttle body off and clean it up.

* 2.5-4.0 ohms

Update: the instruments work!

I drove around my neighborhood a bunch this evening to test the speedometer and odometer and I’m super hyped to report that everything was in working order!

The new bulbs work well too, and what one is telling me is that the overdrive relay is probably broken. That’s the system that either allows or prevents the car from shifting into 4th gear depending on if a button on the side of the gear selector is pushed. Thankfully this part (previously mentioned as the white thing that needed to be pushed out of the way so the glove box could be closed) is cheap so it’s not a big deal.