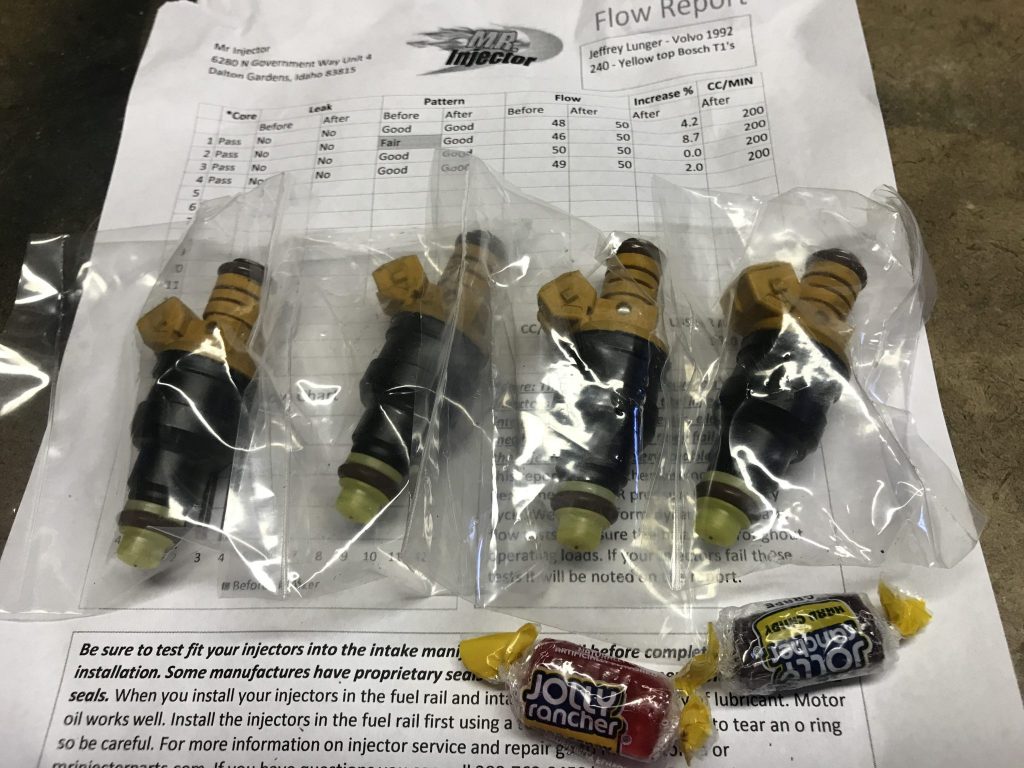

My new Bosch brand ECT sensor has arrived from iPd, so I thought I’d take a moment to talk about part numbers for anyone reading who may also want to replace this part but not know which one to get specifically.

Volvo has part numbers assigned to almost ever piece that goes into their cars. However not every part is actually made by Volvo. Parts that are shared across not only Volvo’s but other company’s cars are usually made by third parties called “original equipment manufacturers” or OEMs. In Volvo’s case, one of the biggest OEMs is Bosch, a German manufacturer of, well, lots of things. Bosch also has a part number for their own products separate from those assigned by the companies that buy from them.

In my case, Volvo’s number for the ECT sensor used in my particular model and year of Volvo is 1346030. Bosch originally numbered this part as 0280130032. However, at some point Bosch decided to renumber this part as 0280130069. Why? I have no idea, but it did leave me scratching my head a little until I gathered enough evidence from the internet to confirm that this is the case.

So I now have a Bosch 0280130069/Volvo 1346030 ECT sensor to replace the FAE 33090 sensor that probably replaced the original Bosch 0280130032.

Crystal clear.