The nasty cut on my hand has sufficiently healed to allow me to fiddle with the car again. I’ll probably have a pretty gnarly scar, but my hand still works and scars can be cool so I won’t complain. It’s also now a new year and I am ready to get to it!

Tool Heaven

There have been several developments since my accident. First, I had the supreme luck to be friends with a person whose parents are downsizing before a move. One of those parents happens to have been a shade tree mechanic himself years ago and had literal mounds of wrenches, sockets and other tools in his garage and basement that needed a new home. Some of them were a little worse for the wear, but, given a little treatment with Evapo-rust coupled with a light coating of oil, they came right back to life. So I’m pretty set for now in terms of the ability to turn bolts and screws.

New Parts

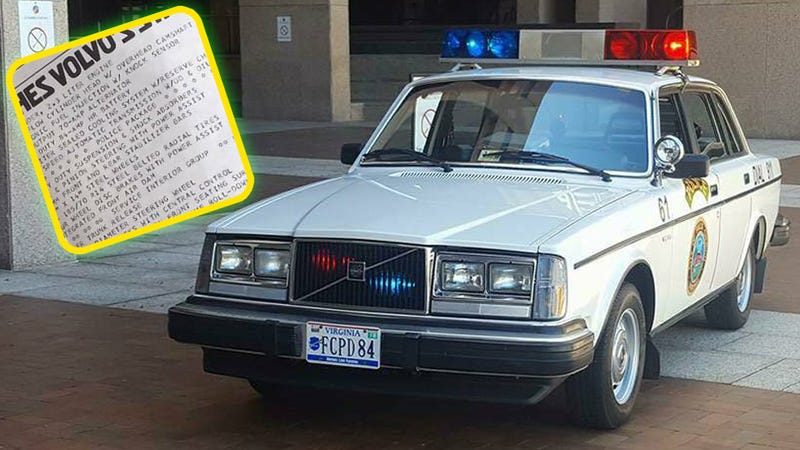

Next, I am happy to say that I managed to snag a set of good condition rear tail lights from a 240-centric Facebook group I’m on, and I got them for what I’d call “a steal.” I’ve not attached them yet as I need to test and clean up all the electrical connections, but they are very nice, especially for the price, and a far sight better than the busted ones my car used to sport.

I am also now in possession of an Engine Coolant Temperature sensor (ECT) and an intake manifold gasket. This is all in preparation for removing the intake assembly, cleaning it up a bit, replacing the ECT, and remounting it all. Additionally, harkening back to that list I found in my glove-box, I have a Fuel Pressure Regulator on the way too. Perhaps I’ll also disassemble the fuel rail and clean it out, or at least remove the injectors and clean them. I’m not sure about that yet, so stay tuned. Even further still, I went and got an overdrive bypass plate from iPd. My plan is to install that and see if I can fix the actual solenoid. If I can manage that I’ll take the bypass back off and reinstall the solenoid.

(Re)Fixing Stuff

Finally, a small amount of actual work. Sort of a revisit to previous work, really. When I had originally installed it, I hadn’t noticed that my pre-pump assembly was missing the rubber o-ring that helped keep the gas fumes from coming from the tank and into the car. So I took it back out, added the o-ring, and then sealed it back up, this time using a new and not corroded to heck lock nut. After a quick test to make sure the pump was still operating I sealed the whole thing back up and reinstalled the floor of the cargo area.

In the process I also located the previously missing center lap belt! One tiny step at a time.